.

.  .

.

Earldoms Brickworks in 1901, 1925 and the site in 1966

There are more detailed versions of these maps below

A Whiteparish local history page from younsmere-frustfield.org.uk

An introduction to the four Whiteparish Brickworks can be found here.

Earldoms Brickworks are shown on the 1901 and 1925 1:2500 Ordnance Survey maps. By the 1966 map the same site was in use as Earldoms Sawmill. The family had sold the business and started a new sawmill immediately to the west.

.

.  .

.

Earldoms Brickworks in 1901, 1925 and the site in 1966

There are more detailed versions of these maps below

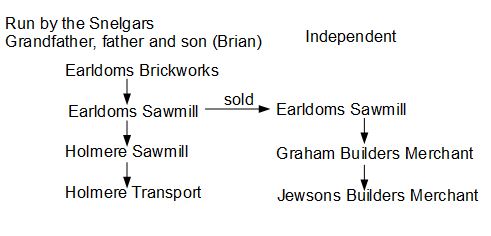

Map and census records of individual brickworks (diagram still being built)

Started by Brian Snelgar's grandfather on the current Jewsons site when he moved to Whiteparish from Fritham. He and Brian's father later started Earldoms Sawmill on the same site, which was later sold as a going business.

There are clay pits behind Brian and Mary's house (Holmere Bungalow) and the whole of the frontage has been used for bricks up to the road. Blue and yellow clay, 40 feet thick I believe he said. The Acre Field was bought as a clay reserve for bricks when they were considering restarting brick making the 1950s (probably Brian's father).

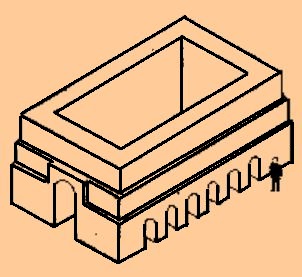

Specialist bricks were made, using a Scotch Kiln, also known as an updraught kiln. There is a very good website on brickmaking in the Isle of Wight with plenty of detail at iwhistory.org.uk, and a comprehensive description with photographs of the entire process of making bricks by this method at Pluckley Brick.

The kiln measured roughly 20 by 12 feet (6.2 by 3.9 metres), measured as accurately as possible from one shown on the 1901 map. A similarly sized building on the 1925 map is likely to be the kiln at that date.

A Scotch kiln typically consists of four brick walls roughly three feet (one metre) thick with firing arches along each side in which wood or coal fires are lit and kept going, typically for three days and nights. Hot gases from the fires pass under a false floor beneath the bricks then up through them. An opening at one end allows access for placing and removing the bricks, often with a second opening at the other end at first floor level to give access to the top of the stack to allow more bricks to be added. Bricks are laid to fill the space, with small gaps between them to allow hot gases to move freely through them. Turf and old bricks cover the top before firing as the building has no roof. The site also had large covered areas for drying the bricks before firing.

A schematic view of a Scotch Kiln from iwhistory.org.uk

Singleton Museum at West Dean in Sussex has a good display of brick making. There is a horse operated mill to mix the clay to an even constituency, moulds for making the bricks and drying racks to ensure moisture is completely removed before firing. [Add my photograph of the old brickworks on the road along the river from Downton to Alderbury.]

See Banke's Copse for further details of the history of this plot and the various businesses that have been run there.

The sequence of businesses run at Holmere by the Snelgars: grandfather, father and son Brian

brickworks site 1876 1-2500.gif)

The site of Earldoms & Holmere Brickworks and Sawmills in 1876

brickworks 1901 1-2500.gif)

Earldoms Brickworks (Holmere) in 1901

brickworks 1925 1-2500.gif)

Earldoms Brickworks (Holmere) in 1925

Holmere Sawmills and Earldoms Sawmills in 1966

Brick making was carried on at several other sites in Whiteparish, including nearby at Chadwell Brick Kiln, at Cowesfield Brickworks and in Whiteparish village at Whiteparish Brickworks on Common Road between the school and church.